|

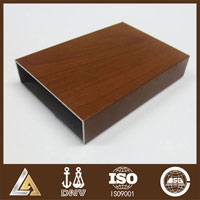

wood grain aluminum profile |

Home >> Aluminium profiles |

Wood grain aluminum profile

Wood grain is thermal transfer printing the wooden texture onto the aluminum profile. For getting better adhesive attraction, pretreatment of thin layers powder coating is needed. then wrap aluminum profiles by pre-printed wooden texture paper and film, curing in a vacuum wood grain machine, affecting the decoration by converting ink pigments from solid into gas and back again to solid within the painting layer, lastly remove the paper and film after cooling. |

|

|

|

|

| wood grain |

wood grain |

wood grain |

wood grain |

| |

|

|

|

|

|

|

|

| wood grain |

wood grain |

wood grain |

wood grain |

|

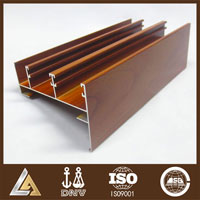

The wood grain effect is achieved by passing the aluminum profiles through two major processes. The first process is powder coating and the second is sublimation. |

The powder coating process may be subdivided into four stages - pre-treatment, base coating, curing and cooling. Base coating involves the coating of the profiles with electrostatically charged colored powder particles. The thermoset particles are sprayed unto the profile in a horizontal and vertical direction to cover all the visible parts of the profile. |

After the coating, the profiles are conveyed to a curing oven. In the curing oven, the particles flow and cover each other through a process known as cross-linking. The particles become fluid and link up with each other to form a smooth layer of coating on the aluminum surface. Normally, the oven is kept at a temperature of 200 degrees Centigrade during the curing phase. The process usually takes a little less than a quarter of an hour. |

From the oven, the profiles are taken to a cooling area. After cooling, they will be taken to the next stage - the sublimation process. The sublimation process has four main stages - film wrapping, vacuuming or air removal, curing, cooling and removal of the film. |

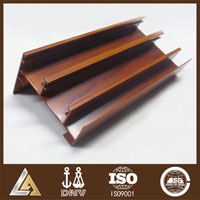

A film paper or sheet containing the desired wood grain or decorative pattern is wrapped on the profile first. After it is placed inside the sublimation machine. Inside the machine, the air space is removed between the film and profile to create a vacuum. |

Then the profiles are placed in a curing oven. As the film and the profile gets heated up, the imprint on the film is transfered to the aluminum surface. After sublimation, the film and the profile cool down together. The film paper is stripped off the profile and the profiles are packaged and shipped to the customer. |

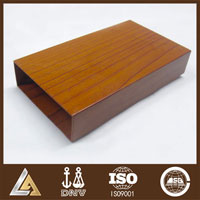

Applications of Wood Grain Finish: |

Windows: Wood grain patterns look great on various kinds of window frames. On casement windows, wood grains give the window space an elegant look and they blend very well with the wood siding and tinted window panes. Similarly, on sliding windows, wood grains give the window a unique appearance and enhance the overall look and feel of the living space.

Using windows with wood grains can help to improve the overall value of a home. It gives a unique vintage appeal to a home. They are perfect for both renovation (retrofit) and new building construction. The natural color of wood makes the home more attractive to new home buyers and also helps to enhance the resale value of a home. |

Doors: Wood grain aluminum profiles are excellent for door frames. They may be used as internal or external door frames. Internally, they may be used for the doors at the kitchen, bedroom, home office, or for any other room within the home. In the same way, doors with wood grain designs can serve as external doors. They may be installed in the spaces for front doors, back doors or patio doors. They offer a high resistance to weather elements and they can withstand the UV rays of the sun.

Doors with wood grain patterns look natural and attractive. Combined with either aluminum, steel or even wood doors, the wood grain frames offer impressive natural beauty and splendor. That's why more architects, building designers, and interior designers are choosing wood grain aluminum profiles to create door frames for their new construction and renovation projects. |

Overall, the wood grain effect is one of the best types of decorative finish used to improve the appearance of aluminum profiles. These decorated profiles are produced with a low cost production process that makes them affordable for various types of architectural designs and construction projects. They are suitable for all types of aluminum doors and windows because of their durability, wear-resistance and aesthetics. |

|

We export aluminium profiles to South Africa, East Africa, West Africa, North Africa market like Algeria, Nigeria, Benin, Ghana, Senegal, Cameroon, Kenya, Tanzania, Ethiopia; And South American market like Brazil, Columbia, Ecuador, Peru, Chile, Argentina, Paraguay, Mexico; Also South-East Asia market like Philippines, Thailand, Vietnam, Burma, Nepal, Malaysia, Indonesia; And Middle East countries like Turkey, UAE, Israel, Iran; And European countries like Russia, Ukraine, Netherland, Poland, Italy, Spain and Australia etc. |