|

triacid polished aluminum profiles for shower room bath cabin |

Home >> Aluminium profiles |

Triacid polished aluminum profile for shower room and bath cabin

Triacid polishing is a kind of chemical polishing method by dipping the aluminum profiles in strong oxidizer to obtain a super bright mirror surface, glossiness over 600. Triacid means three acid liquor of phosphoric acid, sulfuric acid, nitric acid. Firstly profiles are mechanical polished then for triacid polishing to make surface has various styles of shines. 2~4μm oxide layer thickness on aluminum profiles for bathroom and shower room. |

|

|

|

|

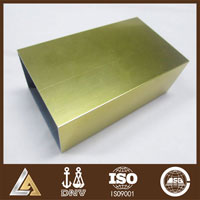

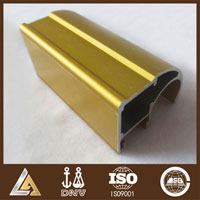

| two acid polished gold |

triacid gold matt |

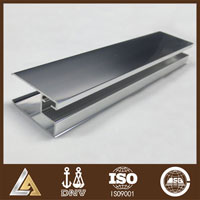

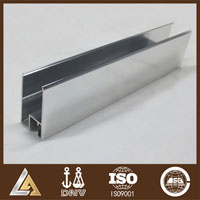

triacid polished silver |

triacid polished silver |

| |

|

|

|

|

|

|

|

| triacid polished aluminum profile |

triacid polished aluminum profile |

|

|

|

The triacid polishing aluminum profiles and two acid polishing aluminum profiles have bright and shiny surfaces and they are used for internal bath screen. With a carefully controlled chemical process, the extruded aluminum profiles pass through different pre-treatment stages and the phosphoric acid and nitric acid bath before they are anodized and sealed to protect the precious bright finish. |

The aluminum profiles are firstly treated by mechanical polishing machine, then go through a pre-cleaning phase to take off all surface scratches and die marks to create a surface that has no surface defects. Then they pass through a well designed cleaning cycle to take off all surface oxides, buffing compounds, and lubricants that may affect the outcome of the brightening process. Subsequently, the profiles are placed in a bath where all microscopic roughness on the surface of the aluminum is leveled. This creates a perfectly reflective surface. After removing the profiles from the bright dip bath, an anodizing process produces a clear protective coating on the profile surface. The final oxide coating closes the pores on the coating and protects the metal from corrosion. |

Our bright dipping process helps to increase the brightness of aluminum, eliminating all the microscopic roughness on the aluminum profile surface. The bath used for two acid aluminum profiles has nitric and phosphoric acids as well as additives to cut down nitrogen dioxide fumes and improve the brightening capacity of the bath, while the triacid aluminum profiles have sulfuric, phosphoric, nitric acid and other additives. |

When aluminum profiles are placed inside a bright dip bath to smoothen out the surface, there must be a quick attack on the higher areas of roughness than the depressed areas. The nitric acid forms a chemical reaction with the aluminum to create a film of aluminum oxide and the phosphoric acid reacts to dissolve this film. These two reactions take place faster at the peaks of the rough areas than at the valleys due to the viscosity of the two-acid solution. As the rate of chemical reaction decreases at the valleys, the amount of aluminum phosphate in the solution increases and the nitric acid is reduced. |

We manage this process carefully to get an optimal balance for effective smoothing of the metal surface. This is very important because the highest amount of brightness will occur when the right amount of metal is taken off during the chemical process. Excessive metal removal usually reduces the image clarity and causes a wavy, bumpy effect on the surface. |

| |

Benefits of Two-acid and Tri-acid Aluminum Profiles

Glossy Clear Finish: Bright dip or acid surface treatment creates a very attractive glossy surface. This glossy finish is suitable for use on door handles and other accessories for shower room and bath screen. The decorative profile may also be tinted to provide a good architectural trim to match various bathroom designs. Thousands of color shades may be used to create the exact color required and the colors can be reproduced to give an exact match on subsequent batches.

Durability: The two-acid and tri-acid aluminum profiles have a durable surface finish. The shiny surface is resistant to corrosion. So it can be used for doors that will be exposed to chemicals in soap and other cleaning solutions as well as the high moisture content and humidity in baths and shower rooms. The profiles offer adequate wear resistance and they don't peel off when exposed to intense heat of hot baths. This aluminum profile also performs well in areas with a relatively high amount of salt water. Due to the glossy film on the aluminum profile, it is resistant to wear, fading and scratching.

Color Stability: Two acid aluminum profiles have a rich, deep metallic sheen. The glossy film is translucent so the aluminum keeps its metallic appearance after the surface treatment. The profiles do not fade or peel and they offer resistance to very high heat used in the bath or hot spa.

Easy Maintenance: Very minimal cleaning is required even when they are used in high traffic environments like public baths and spas. When there is a need for cleaning, very mild cleaning solutions and a wash cloth may be used to take off dirt, oil or grease. The low maintenance requirement also saves a lot of money that could have been required for more expensive commercial cleaning. This also makes the profiles suitable for use in baths for gyms and public places where frequent cleaning may not be feasible because of the number of people using the facility. |

| |

|

We export aluminium profiles to South Africa, East Africa, West Africa, North Africa market like Algeria, Nigeria, Benin, Ghana, Senegal, Cameroon, Kenya, Tanzania, Ethiopia; And South American market like Brazil, Columbia, Ecuador, Peru, Chile, Argentina, Paraguay, Mexico; Also South-East Asia market like Philippines, Thailand, Vietnam, Burma, Nepal, Malaysia, Indonesia; And Middle East countries like Turkey, UAE, Israel, Iran; And European countries like Russia, Ukraine, Netherland, Poland, Italy, Spain and Australia etc. |