|

brushed anodized aluminum profile |

Home >> Aluminium profiles |

Brushed aluminum profile

Brushed aluminum profiles have an attractive satin finish. Brushing is a pre-treatment process that is applied to the surface of the extruded aluminum profiles before anodizing. It gives the metal surface a unique look and it helps to retain the lustre and give a pattern of fine lines. |

|

|

|

|

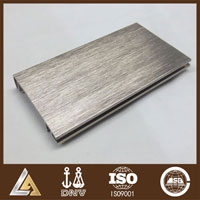

| brushed polished silver aluminum profile |

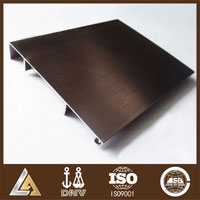

brushed bronze aluminum profile |

brushed aluminum profile |

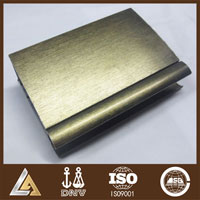

brushed champagne aluminum profile |

| |

|

|

|

|

|

|

|

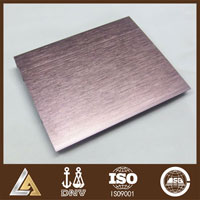

| brushed purple aluminum profile |

brushed bronze aluminum profile |

brushed champagne aluminum profile |

brushed champagne aluminum profile |

|

Brushing creates a unidirectional satin finish and provides a silky-matt finish on profile surface, it gives aluminum a distinctive look, as it retains some but not all of its metallic lustre and is given a pattern of very fine lines parallel to the brushing direction. Aluminum profiles with satin brush finish are frequently used in architecture buildings. |

Brushing is usually performed with a special machine that has a set of rollers and some replaceable brush wheels. A variety of brush wheels are used for this operation. The initial set of brushes in the machine may have a specification of 120 - 180 grit while the final brushing is done with 80 -120 grit wheel. These brushes must be carefully selected to achieve the desired surface effects. |

After the profiles to be brushed are removed from the extrusion die, they are moved to the brushing section with a conveyor or carried manually with a forklift. At the brushing machine, they are placed on a loading table that has a set of rollers. The rollers at the loading table move the profiles into the machine one at a time. |

As the profile comes into the machine, it is gripped by the first brush wheel. This wheel has an abrasive substance known as silicon carbide grit. The grits are arranged around the cylindrical wheel and they create very thin parallel lines that have an attractive satin finish. |

After a section of the profile has passsed through the first grit wheel, it will be moved continuously to the next set of brushes by the rollers in the middle of the machine. At the outlet of the machine the final set of brushes are used to complete the surface treatment. This final set of brushes is usually softer than the first set. That is why they can smoothen the intial brushed surface and reduce the depth of the cut made by the first set of brushes. |

At the outlet, the profiles are released unto another table where an operator is waiting to receive and inspect them. This table serves as a place where the profiles are cooled for a few seconds before they are handled by the operator. After the profiles are removed from the table, they are quickly inspected to see whether the desired effect has been achieved. Then they are removed from the table, and placed on a conveyor or stacked up for movement to the anodizing section with a forklift. |

The brushed aluminum profile that comes out of the machine has a beautiful satin finish and no dust is created during the process. All the profiles come out clean and they do not have any grease or polishing paste on them. Also, all the imperfections that come from the extrusion dies are completely removed. |

|

We export aluminium profiles to South Africa, East Africa, West Africa, North Africa market like Algeria, Nigeria, Benin, Ghana, Senegal, Cameroon, Kenya, Tanzania, Ethiopia; And South American market like Brazil, Columbia, Ecuador, Peru, Chile, Argentina, Paraguay, Mexico; Also South-East Asia market like Philippines, Thailand, Vietnam, Burma, Nepal, Malaysia, Indonesia; And Middle East countries like Turkey, UAE, Israel, Iran; And European countries like Russia, Ukraine, Netherland, Poland, Italy, Spain and Australia etc. |