|

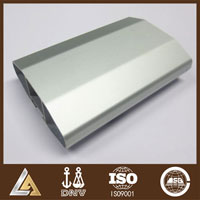

sand blasting anodized aluminum profiles |

Home >> Aluminium profiles |

Sand blasting aluminum profile

Sand blasting is a process by which glass beads, steel grits are shot at very high speed with a blasting machine, unto the surface of the aluminum profiles. This is usually done to take off any die and extrusion streaks and create a matt surface before anodizing. |

|

|

|

|

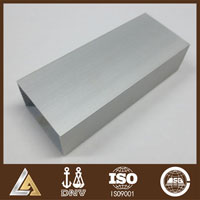

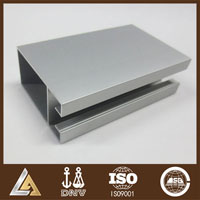

| alkali matt anodized silver |

glass beads sand blasting anodized silver matt |

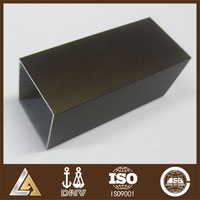

glass beads sand blasting anodized bronze matt |

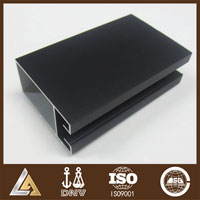

glass beads sand blasting anodized black matt |

| |

|

|

|

|

|

|

|

| sand blasting anodized silver matt |

sand blasting anodized champagne matt |

sand blasting anodized bronze matt |

sand blasting anodized black matt |

| |

|

|

|

|

|

|

|

| sand blasting anodized gold matt |

sand blasting anodized silver matt |

|

|

|

Sand blasting is one of the profile surface pretreatments, which tends to create a matt dull surface by propelling a stream of abrasive fine glass or steel beads at a high pressure to smooth mill finish profiles without getting damaged. Sand blasting serves as a pre-treatment method that functions as a cleaning and finishing process. To get the most suitable matt finishing effect, we control factors such as abrasive hardness, particle size, velocity of the abrasive particles, angle of the gun or blasting machine and the method of application. As a pre-treatment process, sandblasting is done before anodizing and electrophoresis procedures. After sandblasting has been completed, aluminum profiles are ready for anodizing bath. |

Several factors affect the effectiveness of the sandblasting process and the desired surface finish. The most prominent include: pressure, the sandblasting gun, the gun nozzle, and the type of abrasive media. The amount of pressure applied to the aluminum profile is determined by the type of machine used. Sandblasting at a very high pressure will cause the surface to break down quickly, while at a lower pressure, there will less warping and hardening of the profile surface. |

The matt finish is produced by positioning the gun at an angle to the aluminum profile surface. Care is taken to avoid positioning the gun at a right angle so that peening does not occur and wear out the surface of the extruded aluminum. With our direct pressure machine the profiles are kept at a distance that allows the spray of the abrasive from the gun to cover a large area so the pattern can overlap and produce a more visually appealing matt finish. |

The gun nozzles we use are made of tough materials like tungsten carbide which is the most suitable choice for sandblasting. The nozzle size is carefully matched to the pressure produced by the compressor. The pressure at the gauge must match the blaster and produce the right pressure at the gun. The nozzle ensures that the pressure at the gun delivers a consistent flow of the abrasive material. |

Benefits of Sand blasting:

Efficient Surface Cleaning: Sandblasting removes oil stains, mill scale, and other contaminants and surface dirt that may form on the profile surface of the extruded aluminum profiles. During blasting, the abrasive material cleans out all dirt, grease, and irregular marks on the surface of the extruded aluminum.

Cost savings: Sandblasting is considered to be an economical pre-surface treatment technique. the same abrasive material may be used many times for the blasting process. This is a recyclable asset and it helps to reduce the cost of the process and makes it one of the most economical choices for pre-treatment of aluminum profiles.

Better bonding: After sand blasting aluminum profiles, they have a larger surface area for a better bonding during further surface treatment. Some estimates put the increase in total surface area at up to 10 times what was available before the abrasive impact. This expands the area to which any type of coating, plating or painting will adhere.

Desired surface texture: Sand blasting gives us an excellent matt surface of the aluminum profile surface before it is anodized. Depending on the pressure of the sandblasting gun and steel grits mesh size, rough and fine matt surface may be achieved. |

| |

|

We export aluminium profiles to South Africa, East Africa, West Africa, North Africa market like Algeria, Nigeria, Benin, Ghana, Senegal, Cameroon, Kenya, Tanzania, Ethiopia; And South American market like Brazil, Columbia, Ecuador, Peru, Chile, Argentina, Paraguay, Mexico; Also South-East Asia market like Philippines, Thailand, Vietnam, Burma, Nepal, Malaysia, Indonesia; And Middle East countries like Turkey, UAE, Israel, Iran; And European countries like Russia, Ukraine, Netherland, Poland, Italy, Spain and Australia etc. |